Fault Detections, Diagnostics, and Prognostics of Power Grid Assets

Contact: Dr. Blazhe Gjorgiev

The power system operators regularly maintain their assets in order to uphold high system reliability. The maintenance schemes that are in use nowadays are, in many cases, based on preventive maintenance wherein the assets are maintained at fixed intervals. Doing so, assets are systematically replaced even though some of them could remain in use for a longer time. Furthermore, the risk of asset failing before their planned maintenance/replacement still exists. This opens the way for third generation maintenance schemes, which implements predictive maintenance on transmission system assets. This scheme would use data-driven techniques to detect abnormal operations and ultimately estimate the time to failure of a component.

Within RRE we aim at exploring data-driven methods for the development of tools for fault detection, diagnostics and prognostics of power grid assets. Currently, we focus on power lines and transformers as the most critical grid components. Besides reducing the costs for operation and maintenance, the developed tools aim at improving the reliability of power supply to costumers.

Image Recognition for Detection and Classification of Faulty Power Line Components

The power lines consists of multiple components including towers, insulators, fittings, and conductors. The operational conditions as well as the environment affect these components; therefore, there is the need for regular inspections, maintenance, and replacements. Many of the faults on the components such as damaged insulator (missing/broken cap, discoloration due to arcing/lightning strike), rust on the tower, foreign objects in the tower (branches, bird nests), and missing part of a fitting can be detected by visual inspection. We are developing image detection methods based on deep learning to identify the various objects on a tower and classify them as healthy or faulty. Besides separate models for detection and classification of the different objects, we aim to develop end-to-end model that is able to detect all objects of an image and classify them.

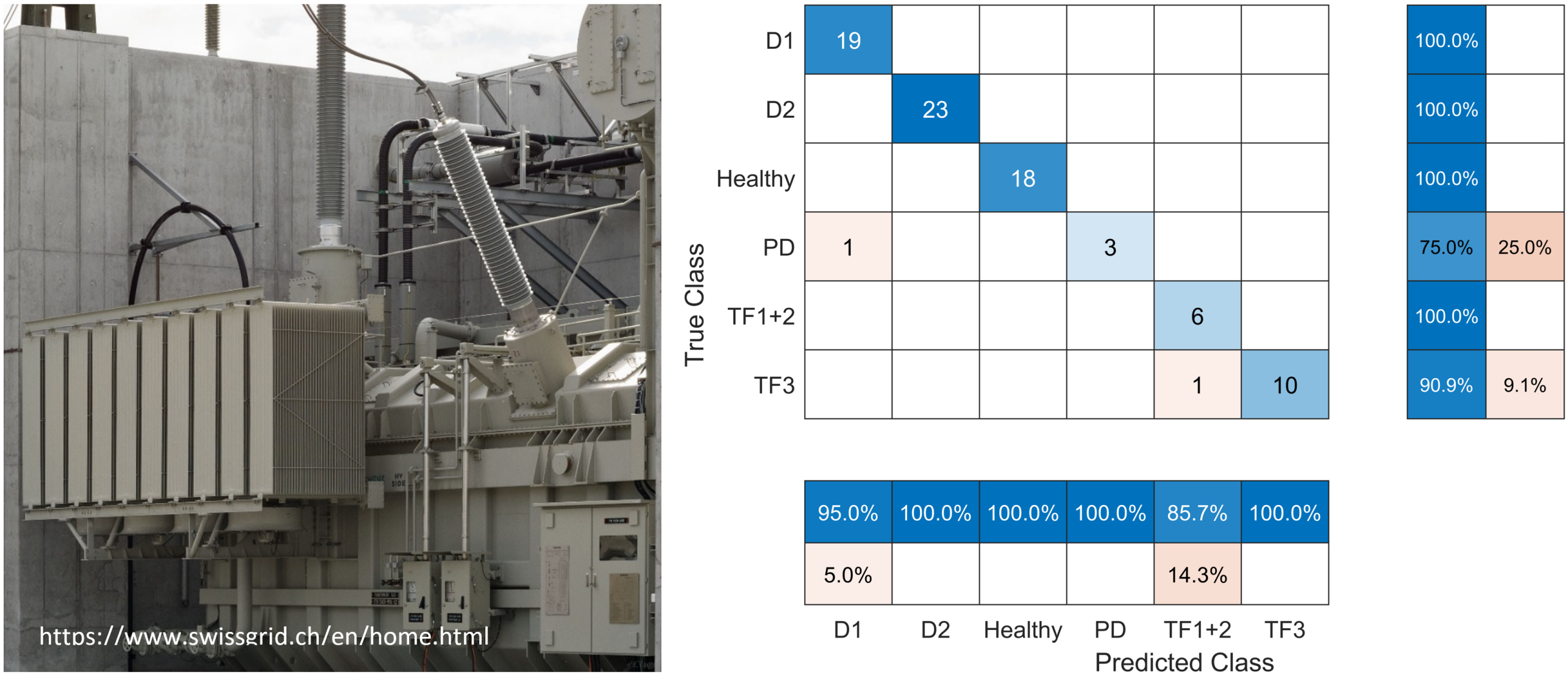

Machine Learning Based Fault Detection and Diagnostics of Power Transformers

Power transformers are one of the most essential and expensive components to operate and maintain within power systems. Failure of the transformer may lead to high repair cost or irreversible internal damages. Furthermore, failure can result in the interruption of the power supply to consumers as well as economic consequences for grid and plant owners. Considering these serious effects of transformer failures for grid operations, an urgent need is given for monitoring the transformers health, detect and classify faults at an early stage and taking the right maintenance action at the right time.

We utilize Machine Learning methods to interpret Dissolved Gas Analyses (DGA) data and to identify and classify faults in a power transformer. The DGA data is gathered from different open source libraries including the IEC TC 10 database. The fault classification is based on the IEC Publication 60599: 1) partial discharge (PD); 2) discharge of low energy (D1); discharges of high energy (D2); thermal faults below 300 oC if paper has turned brownish (T1), above 300 oC if paper has carbonized (T2); and thermal faults above 700 oC (T3). We have used 6 classes (including normal state and combined T1 and T2 into one class). We have applied a range of machine learning methods including, decision trees (DT), support vector machine (SVM), k-nearest neighbors (KNN), various Ensemble classifiers, and artificial neural networks (ANN). The best results we have obtained with optimizable KNN (uses Bayesian optimization for the hyper-parameter identification), DT and Bagged Trees ensemble with an accuracy of up to 97.5% on a test data set.

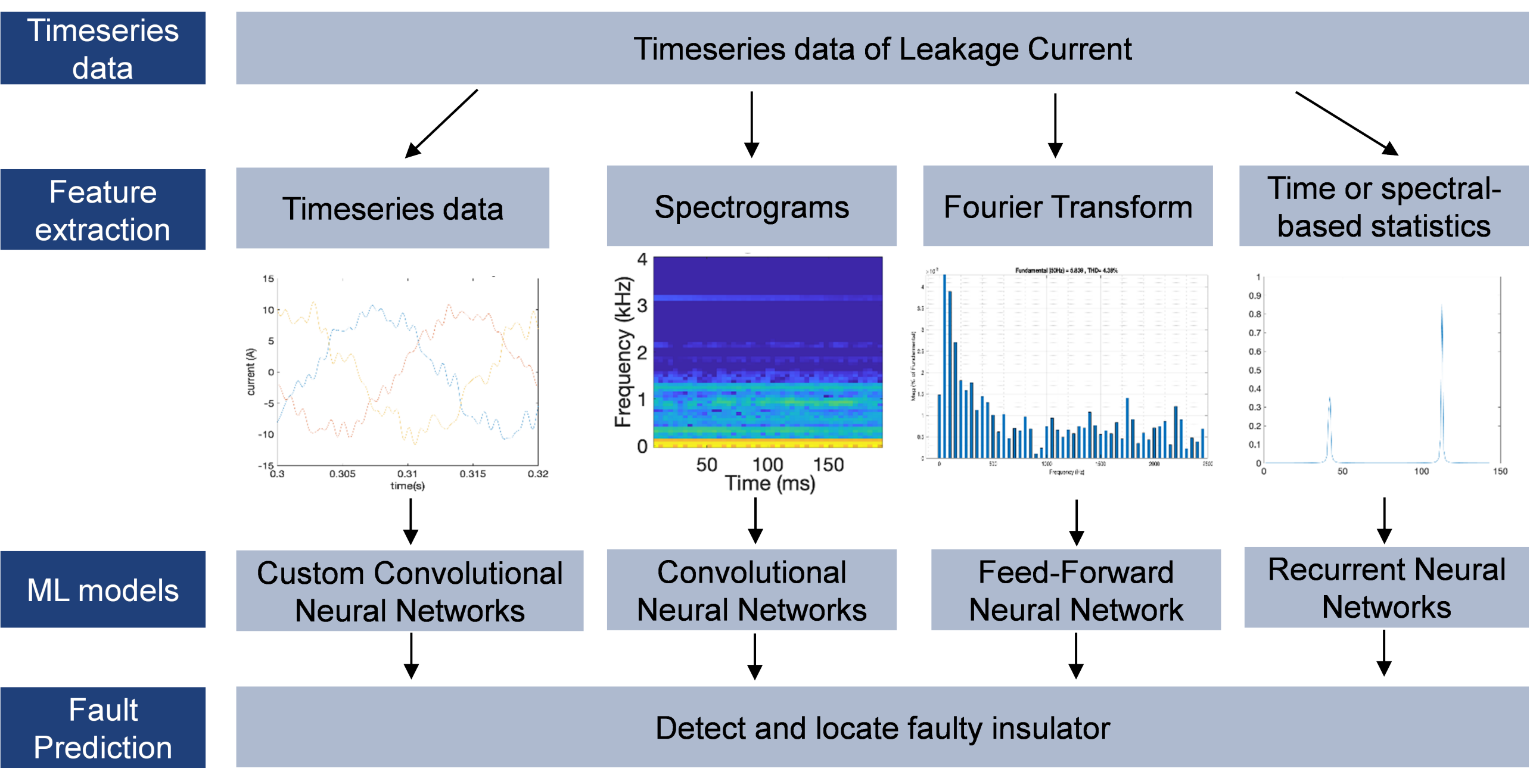

Physics-Informed Deep Learning for Detection and Location of Faulty Insulators

Majority of the power system faults are known to occur in transmission lines (TLs). The maintenance of the TLs is crucial to avoid unplanned outages. However, the current maintenance schemes are expensive, as they are based on regular inspections and replacements. Predictive maintenance offers an improved maintenance scheme. It offers detection of abnormal operations and avoids unnecessary asset replacements, which reduces costs and improves reliability.

As the insulation properties of the insulators decrease, more current is allowed to leak towards the ground, referred to as leakage current. In our work, we exploit the leakage current to detect the state of health of insulators as well their location in the power line. Measurement data on leakage current for different insulators under different states of health in not available. Therefore, we have leveraged a physics-based model of a transmission line, which is developed in Simulink/MATLAB and is able to simulate the leakage current. The model is calibrated using real data from the transmission line. Different faulty conditions are simulated and a dataset is generated. The labelled dataset is then used to train machine learning algorithms, namely feed-forward neural networks, long short-term memory, and convolutional neural networks to detect, classify and locate potential faults in the transmission line. Results show that it is possible to classify potential faults with an accuracy of up to 95% and locate them with an accuracy of up to 98%.